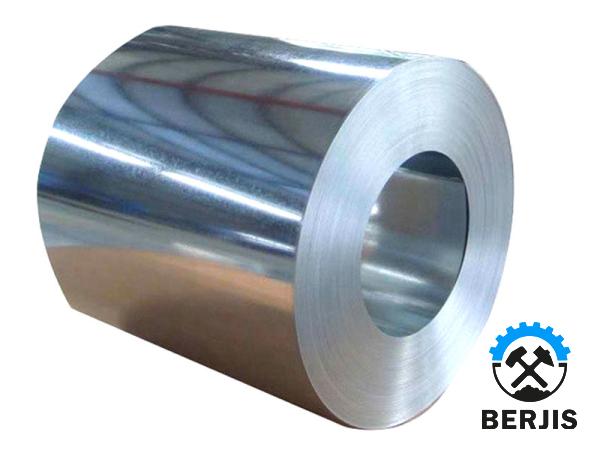

Cold rolled steel sheet is a versatile material that plays a critical role in various industries. This article will delve into the world of cold rolled steel sheet, exploring its manufacturing process, key attributes, advantages, and diverse applications across different sectors. 1. The Manufacturing Process of Cold Rolled Steel Sheet: Cold rolled steel sheet is produced through a multi-step process that involves the removal of scale and surface imperfections from hot rolled steel. The manufacturing steps include: a) Hot Rolling: The initial step involves passing molten steel through large rollers to create hot rolled steel coils. b) Pickling: The hot rolled coils are immersed in an acid solution to remove scale and impurities, enhancing their surface finish.

.

c) Cold Reduction: The pickled coils undergo cold rolling, where they are gradually passed through multiple rolls to reduce thickness while improving dimensional accuracy. d) Annealing: After cold rolling, the steel is annealed to optimize its strength, hardness, and ductility. 2. Key Attributes and Benefits of Cold Rolled Steel Sheet: Cold rolled steel sheet possesses several advantageous characteristics that make it highly sought-after in various industries: a) Superior Surface Finish: The pickling and cold reduction process results in a smooth and clean surface, making cold rolled steel sheet suitable for applications that require a polished appearance. b) Tighter Dimensional Tolerances: Cold rolling ensures precise thickness control, enabling manufacturers to achieve tighter dimensional tolerances and uniformity in the finished product. c) Improved Strength and Formability: Cold rolling increases the strength of the steel, making it ideal for applications that demand high strength and excellent formability. d) Enhanced Workability: Cold rolled steel sheet can undergo further processing, such as bending, punching, and welding, without compromising its structural integrity.

c) Cold Reduction: The pickled coils undergo cold rolling, where they are gradually passed through multiple rolls to reduce thickness while improving dimensional accuracy. d) Annealing: After cold rolling, the steel is annealed to optimize its strength, hardness, and ductility. 2. Key Attributes and Benefits of Cold Rolled Steel Sheet: Cold rolled steel sheet possesses several advantageous characteristics that make it highly sought-after in various industries: a) Superior Surface Finish: The pickling and cold reduction process results in a smooth and clean surface, making cold rolled steel sheet suitable for applications that require a polished appearance. b) Tighter Dimensional Tolerances: Cold rolling ensures precise thickness control, enabling manufacturers to achieve tighter dimensional tolerances and uniformity in the finished product. c) Improved Strength and Formability: Cold rolling increases the strength of the steel, making it ideal for applications that demand high strength and excellent formability. d) Enhanced Workability: Cold rolled steel sheet can undergo further processing, such as bending, punching, and welding, without compromising its structural integrity.

..

e) Reduced Risk of Rusting: The pickling process removes scale and impurities, providing better corrosion resistance than hot rolled steel. 3. Applications of Cold Rolled Steel Sheet: Cold rolled steel sheet finds diverse applications across numerous industries: a) Automotive Industry: Cold rolled steel is widely used in automobile manufacturing due to its exceptional strength, formability, and superior surface finish. It is utilized in body panels, chassis, frames, and various components. b) Construction and Infrastructure: Cold rolled steel is used in the construction of buildings, bridges, and infrastructure projects. Its high strength and dimensional accuracy make it suitable for structural applications. c) Appliances and Electronics: Cold rolled steel sheet is used in the manufacturing of kitchen appliances, air conditioning systems, and electrical equipment due to its attractive appearance and corrosion resistance.

e) Reduced Risk of Rusting: The pickling process removes scale and impurities, providing better corrosion resistance than hot rolled steel. 3. Applications of Cold Rolled Steel Sheet: Cold rolled steel sheet finds diverse applications across numerous industries: a) Automotive Industry: Cold rolled steel is widely used in automobile manufacturing due to its exceptional strength, formability, and superior surface finish. It is utilized in body panels, chassis, frames, and various components. b) Construction and Infrastructure: Cold rolled steel is used in the construction of buildings, bridges, and infrastructure projects. Its high strength and dimensional accuracy make it suitable for structural applications. c) Appliances and Electronics: Cold rolled steel sheet is used in the manufacturing of kitchen appliances, air conditioning systems, and electrical equipment due to its attractive appearance and corrosion resistance.

…

d) Furniture and Shelving: The smooth surface and excellent formability of cold rolled steel make it a preferred choice for furniture, storage shelves, and industrial racking systems. e) Packaging Industry: Cold rolled steel sheet is used to manufacture packaging materials, including cans and tinplates, due to its superior strength and corrosion resistance. Conclusion: Cold rolled steel sheet offers a multitude of benefits, making it an indispensable material across a wide range of industries. Its excellent surface finish, dimensional accuracy, and enhanced strength make it suitable for diverse applications, ranging from automotive and construction to appliances and packaging. By understanding the manufacturing process and the attributes of cold rolled steel sheet, businesses can make informed decisions regarding its utilization, leading to improved product quality and performance.

d) Furniture and Shelving: The smooth surface and excellent formability of cold rolled steel make it a preferred choice for furniture, storage shelves, and industrial racking systems. e) Packaging Industry: Cold rolled steel sheet is used to manufacture packaging materials, including cans and tinplates, due to its superior strength and corrosion resistance. Conclusion: Cold rolled steel sheet offers a multitude of benefits, making it an indispensable material across a wide range of industries. Its excellent surface finish, dimensional accuracy, and enhanced strength make it suitable for diverse applications, ranging from automotive and construction to appliances and packaging. By understanding the manufacturing process and the attributes of cold rolled steel sheet, businesses can make informed decisions regarding its utilization, leading to improved product quality and performance.